Gearbox efficiency simulation

A number of blocks of the "Mechanics" library are designed to simulate various kinds of gearboxes and gears with friction losses in the gear mesh. The loss rate is characterized by the efficiency of the gearbox. For clarity, the approach to simulate the efficiency of gearboxes will be described on the example of a gearbox, both shafts of which rotate. To generalize, the physical dimensions of the quantities will be omitted, since the described approach is also applicable for the translatory motion of the gear transmission elements.

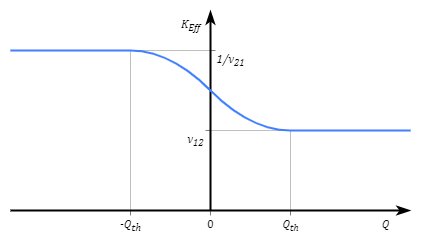

Dependence of efficiency on the direction of power transmission

- when transmitting power from the driving shaft to the driven shaft:

- when transmitting power from the driven shaft to the driving shaft:

- T1 and T2 – torques on the driving and driven shafts of the gearbox, respectively

- ν12 – efficiency of the gearbox when transmitting power from the driving shaft to the driven shaft

- ν21 – efficiency of the gearbox when transmitting power from the driven shaft to the driving shaft

The value of Qth determines the power threshold below which the efficiency value will differ from the specified one.

Ways to define the efficiency

- "No loss" – efficiency of the gear mesh is assumed to be equal to 1

- "Constant efficiency" – gear mesh efficiency has a constant value

- "Variable efficiency on load" – efficiency value is calculated analytically depending on the current values of torques on the gearbox shafts

- "Table data efficiency on load" – efficiency value is calculated by linear interpolation of the table data depending on the current values of torques on the gearbox shafts

- "Table data efficiency on temperature" – efficiency value is calculated by linear interpolation of the table data depending on the current values of torques on the gearbox shafts

Regardless to a way to define gear mesh loss the bearing friction loss of a gearbox may be defined separately using the corresponding coefficients of bearing friction.

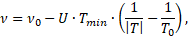

Variable efficiency on load

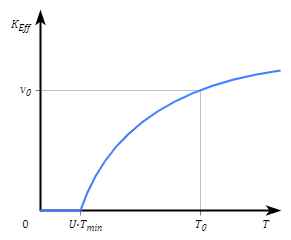

- ν – calculated efficiency value

- ν0 – efficiency at the rated load

- T0 – rated torque at the driven shaft, Nm

- Tmin – the minimum torque at the driving shaft required for motion start, Nm

- T – current torque value at the driven shaft, Nm

The calculated efficiency value is limited by zero from below. In this case the driving shaft is that from which the power is being taken, and the driven shaft is that to which the power is transmitted.

The value defines the torque at the driven shaft that corresponds to the torque at the driving shaft.